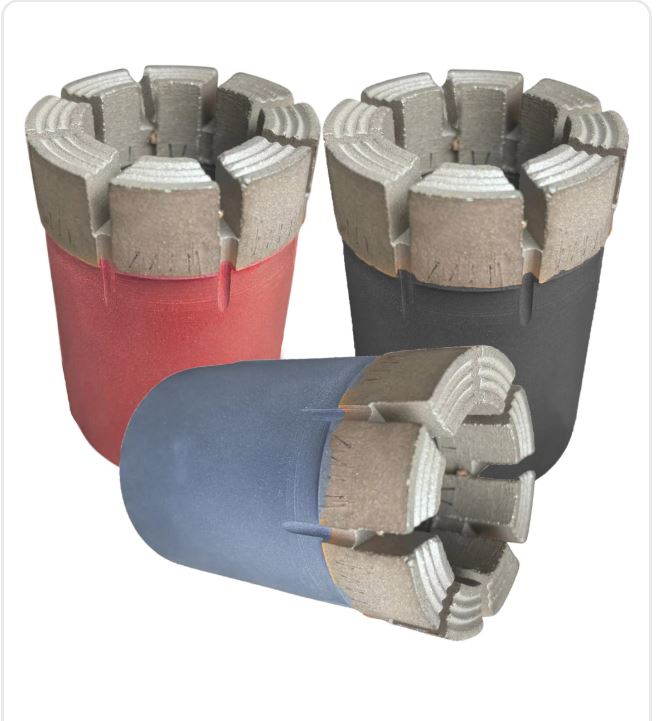

Conventional Coring

Conventional core drilling is a process where drill bits are lowered into the borehole on the end of a drill string, or drill pipe, and rotated manually to create a hole. In this method, the drill bit is connected to the bottom of the drill rod, while the top of the drill rod is connected to the drilling rig’s power source. The drill bit is then rotated, and the drill is slowly lowered into the rock formation. When the drilling reaches a desired depth or a formation boundary, the drill bit is removed, and a core sample is extracted.

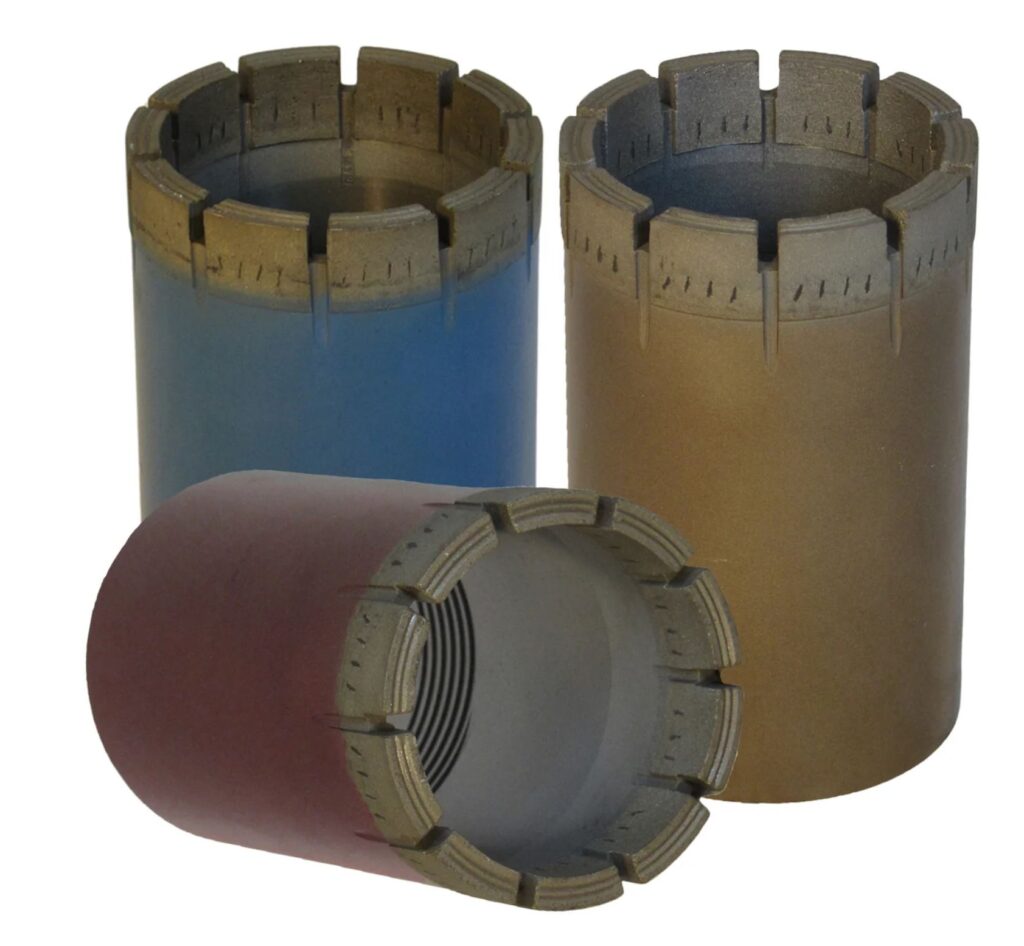

T2-76 Coring Drill Bits

With our full range no rock formation is out of bounds. Build to fit a T2 barrel, these bits have a outer diameter of 76mm (3 Inches) and an inner coring dimeter of 62mm (2.4 Inches), making them ideal for consistently solid exploration samples.

T6-76 Coring Drill Bits

Build to fit a T6 barrel, these bits have a outer diameter of 76mm (3 Inches) and an inner core diameter of 62mm (2.4 Inches), making them ideal for consistently solid exploration samples

T2-86 Coring Drill Bits

With our full range of Coring Drill Bits,no rock formation is out of bounds. Build to fit a T2 barrel, these bits have a outer diameter of 86mm (3.4 Inches) and an inner coring dimeter of 72mm (2.8 Inches), making them ideal for consistently solid exploration samples.

T6-86 Coring Drill Bits

these bits have a outer diameter of 86mm (3.4 Inches) and an inner coring dimeter of 72mm (2.8 Inches), making them ideal for consistently solid exploration samples.

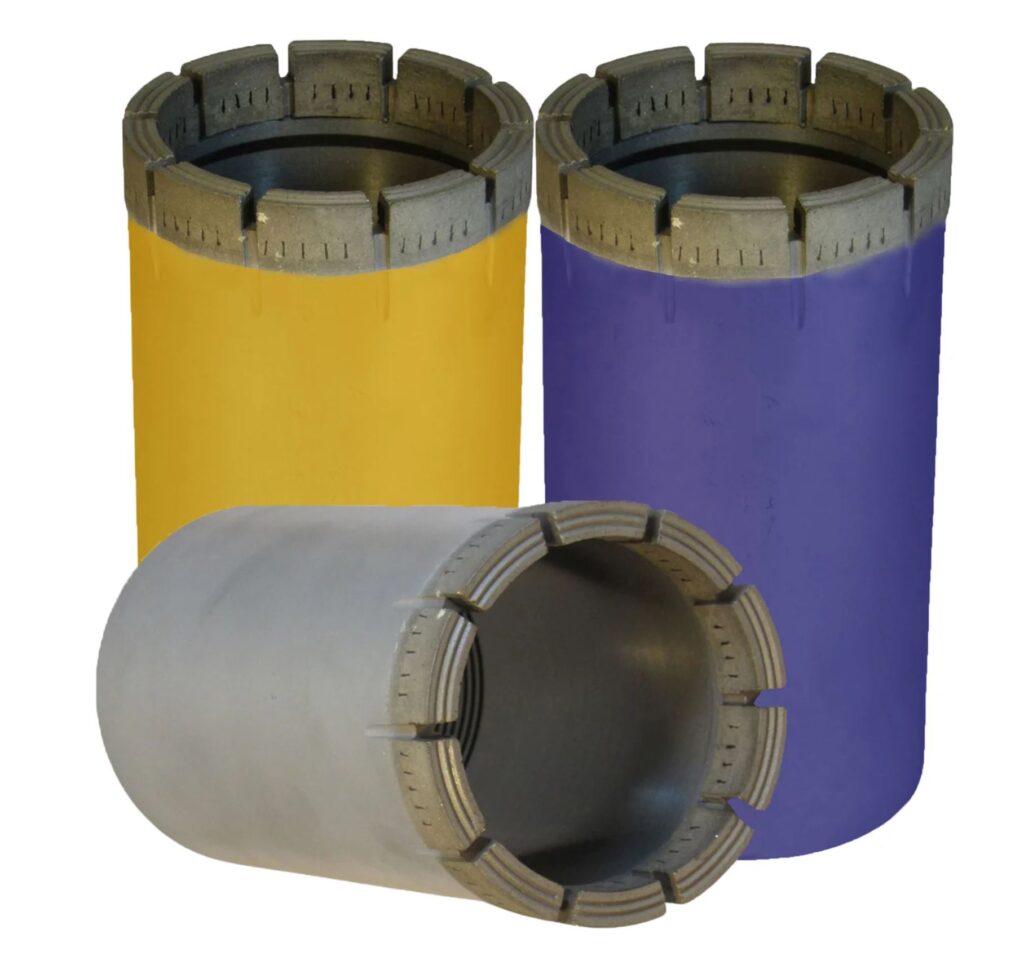

T2-101 Coring Drill Bits

hese bits have a outer diameter of 101mm (4 Inches) and an inner coring dimeter of 84mm (3.3 Inches), making them ideal for making bore holes.

T6-101 Coring Drill Bits

these bits have a outer diameter of 101mm (4 Inches) and an inner coring dimeter of 84mm (3.3 Inches), making them ideal for making bore holes.

T2-116 Coring Drill Bits

With our full range of Set to Liner conventional bits, no rock formation is out of bounds. Build to fit a T2 barrel, these bits have a outer diameter of 116mm (4.5 Inches) and an inner coring dimeter of 99mm (3.9 Inches), making them ideal for making bore holes.

T6-116 Coring Drill Bits

With our full range of Set to Liner conventional bits, no rock formation is out of bounds. Build to fit a T6 barrel, these bits have a outer diameter of 116mm (4.5 Inches) and an inner coring dimeter of 99mm (3.9 Inches), making them ideal for making bore holes.

Conventional Core Barrels Components

Primarily used in mining, oil and gas exploration and geotechnical engineering. Conventional Core Barrels are used to extract cylinder samples of rock sediment from a formation. During the Drilling process the core barrel is lowered into the borehole and rotation is applied to the entire assembly. As the core bit or cutting shoe penetrates the subsurface, it cuts a cylindrical selection of rock or sediment. The core sample enters the inner tube and is collected within it. Conventional core barrels are typically used in shallow to medium depth drilling applications and their design may vary depending on the specific requirement of the project.

Optimize your core drilling operations with the T2-76 Lifter Case - Standard, a meticulously designed component crafted for secure and efficient core handling. Engineered to meet industry standards, this lifter case provides a reliable housing for T2-76 core lifters, ensuring controlled and safe lifting of core samples during drilling.

T2-76 Impreg Reaming Shell

Enhance your core drilling efficiency with the T2-76 Impregnated Reaming Shell. Meticulously crafted for precision and durability, this reaming shell is designed to improve the quality and efficiency of core drilling operations, ensuring optimal performance in geological exploration.

T2-76 Extension Tube

Empower your core drilling capabilities with the T2-76 Extension Tube. Meticulously engineered for seamless integration and durability, this extension tube is designed to extend the reach of T2-76 core bits, providing versatility and precision in drilling operations.

T2-76 Core Lifter - Standard

Elevate the efficiency and reliability of your core drilling operations with the T2-76 Core Lifter - Standard. Meticulously crafted for precision and durability, this core lifter is designed to facilitate the secure and efficient retrieval of core samples, ensuring optimal performance in geological exploration and data collection.

T2-76 Core Lifter - Set to Liner

Enhance the efficiency and reliability of your core drilling operations with the T2-76 Core Lifter - Set to Liner. Meticulously crafted for precision and durability, this core lifter set is designed to facilitate the secure and efficient retrieval of core samples, ensuring optimal performance in geological exploration and data collection, especially when using liners.

T2-86 Tungsten Carbide Reaming Shell

Enhance the efficiency and durability of your core drilling operations with the T2-86 Tungsten Carbide Reaming Shell. Meticulously crafted for precision and toughness, this reaming shell is designed to optimize the quality and efficiency of core drilling operations, ensuring exceptional performance in geological exploration.

T2-86 Lifter Case - Standard

Optimize your core drilling operations with the T2-86 Lifter Case - Standard, a meticulously designed component crafted for secure and efficient core handling. Engineered to meet industry standards, this lifter case provides a reliable housing for T2-86 core lifters, ensuring controlled and safe lifting of core samples during drilling.

T6-101 Core Barrel With Head Assembly

Uncover the true potential of core sampling with the T6-101 Core Barrel and its innovative Head Assembly. Engineered to meet the rigorous demands of professionals engaged in geological and environmental exploration, this state-of-the-art system sets a new benchmark for precision and reliability.

Wireline Coring Bits

Wireline drilling, compared with conventional drilling, is a more advanced drilling technique that uses a specialized cable or wire to retrieve core samples. In wireline drilling, the drill bit is separated from the drill string by a wireline cable, which runs down the borehole. After the core bit cuts through the rock, the core barrel is lifted up the casing by the wireline cable. This process is repeated until the desired depth is reached. Unlike conventional drilling, wireline drilling allows the drill string and mud-rotary system to remain in place, reducing the drill time and improving core recovery rates.

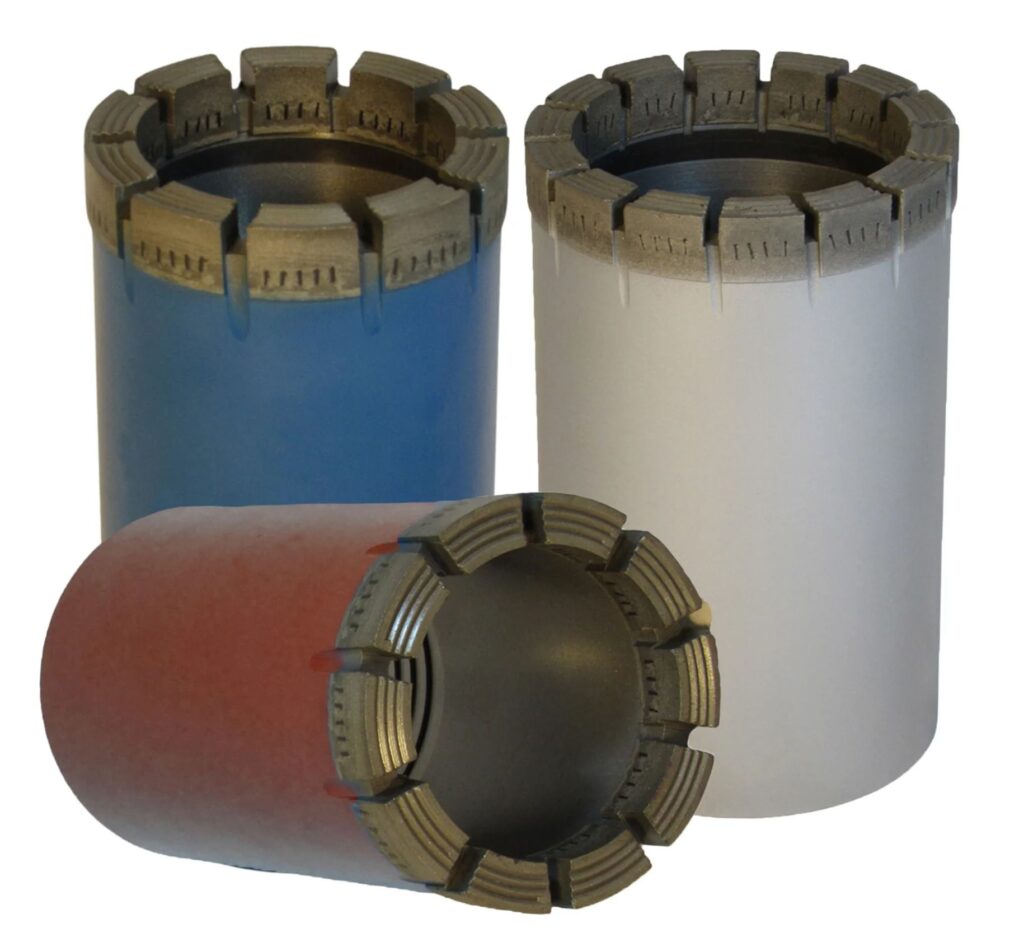

Our range of BWL coring drill bits are made to the highest quality. Built to last, these Kestrel Standard bits are among the most popular bits that are used in the industry. The BWL core barrel has an overall diameter of 59.69mm or 2.35 Inches, with a coring (inside) diameter of 36.52mm or 1.44 Inches. The sturdy barrel and decent sample size makes BWL one of the most popular forms of wireline core extraction.

BWL3 Coring Drill Bits

Our range of BWL3 coring drill bits are made to the highest quality. Built to last, these Eagle Set to Liner bits are among the most popular bits that are used in the industry. The BWL3 core bits have an overall diameter of 59.69mm or 2.35 Inches, with a coring (inside) diameter of 36.52mm or 1.44 Inches. Providing a smaller diameter than other standard core barrel size diameters.

NWL Coring Drill Bits

Our range of NWL coring drill bits are made to the highest quality. Built to last, these Kestrel Standard bits are among the most popular bits that are used in the industry. The NWL core bits have an overall diameter of 75.7mm or 4 Inches, with a coring (inside) diameter of 47.6mm or 1.87 Inches. The sturdy barrel and decent sample size makes NWL one of the most popular forms of wireline core extraction. The sturdy barrel and decent sample size makes NWL one of the most popular forms of wireline core extraction.

NWL3 Coring Drill Bits

Our range of NWL3 coring drill bits are made to the highest quality. Built to last, these Eagle Set to Liner bits are among the most popular bits that are used in the industry. The NWL3 core bits have an overall diameter of 75.7mm or 4 Inches, with a coring (inside) diameter of 47.6mm or 1.87 Inches , allowing for a medium size, rigid core extraction samples.

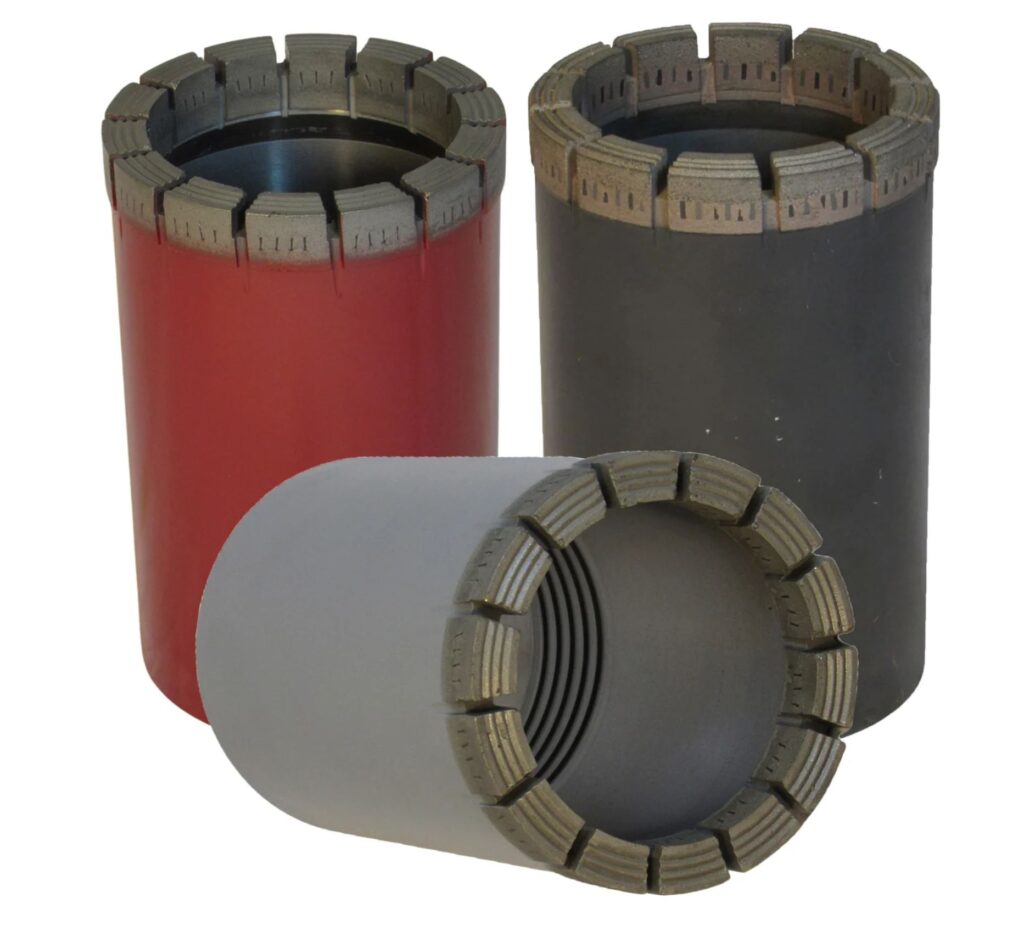

HWL Coring Drill Bits

Our range of HWL coring drill bits are made to the highest quality. Built to last, these Kestrel Standard bits are among the most popular bits that are used in the industry. The HWL core barrel has an overall diameter of 95.76mm or 3.77 Inches, with a coring (inside) diameter of 63.63mm or 2.5 Inches. The sturdy barrel and decent sample size makes HWL one of the most popular forms of wireline core extraction.

HWL3 Coring Drill Bits

Our range of HWL3 coring drill bits are made to the highest quality. Built to last, these Eagle Set to Liner bits are among the most popular bits that are used in the industry. The HWL3 core bits have an overall diameter of 95.76mm or 3.77 Inches, with a coring (inside) diameter of 63.63mm or 2.5 Inches. Providing a smaller diameter than other standard core barrel size diameters.

PWL Coring Drill Bits

Our range of PWL coring drill bits are made to the highest quality. Built to last, these Kestrel Standard bits are among the most popular bits that are used in the industry. The PWL core bits have an overall diameter of 122.6mm or 4.8 Inches, with a coring (inside) diameter of 85mm or 3.3 Inches. The sturdy barrel and decent sample size makes PWL one of the most popular forms of wireline core extraction.

PWL3 Coring Drill Bits

Our range of PWL3 coring drill bits are made to the highest quality. Built to last, these Eagle Set to Liner bits are among the most popular bits that are used in the industry. The PWL3 core bits have an overall diameter of 122.6mm or 4.8 Inches, with a coring (inside) diameter of 85mm or 3.3 Inches, allowing for larger, sturdier core extraction samples.

Our Steel Tooth Tricone Bit models are designed with long "A" shaped teeth, widely spaced and fully hard faced from crest to root for maxiumum penetration rates in formations that range from moderately soft to medium soft. These Steel tooth bits are a type of roller cone bit used to drill though rock with minimum damage to the bit. The bits have have three cones mounted in a conial block. Each cone ends in a griding wheel that resembles a cog wheen with sharpened teeth around its rim.

Tungsten Carbide Insert Bits

Discover excellence in drilling with our Tungsten Carbide Insert (TCI) Bits Collection. Engineered for durability and optimized for superior performance, each bit in this collection is crafted to meet the demands of diverse geological formations. From precision-engineered cutting structures to robust Tungsten Carbide Inserts strategically placed on the cones, these bits guarantee extended lifespan, optimal penetration rates, and reliable results. Choose our TCI Bits Collection for versatile solutions, delivering unparalleled efficiency across a range of drilling applications.

Full Faced PCD Bits

We offer a wide range of full-hole drill bits with polycrystalline diamond cutters (PCD) which are used for numerous applications in mining, civil engineering and the oil and gas industries. These span between small bits 3” diameter used in mines for drilling holes for roof-bolts to larger diameter bits used for horizontal drilling. All these bits have a full tungsten carbide matrix crown imparting a much superior wear resistance than equivalent steel-head bits. PDC drill bits easily beat the performance of conventional roller cone bits, in some cases achieving 10-20 times bit life and 2-3 times the rate of penetration due to their robust structure and heavy weight.

Stepped Drag Bits

Stepped drag bits are a type of drill bit used for drilling holes in soft to medium-hard formations such as sandstone, shale, and clay. These bits are designed with a stepped profile, which means that they have different sizes of cutting elements placed at intervals along the length of the bit. The cutting elements on stepped drag bits are typically made of tungsten carbide or diamond inserts, which provide high wear resistance and durability. The stepped design allows the bit to penetrate the formation more efficiently and reduces the risk of getting stuck in the hole.

Top Hammer Bits

Top hammer bits consist of a steel body with cemented carbide buttons or inserts on the face of the bit. These buttons are arranged in a pattern that maximizes the drilling efficiency and reduces wear on the bit. The carbide buttons are made from a tough and wear-resistant material, which allows the bit to maintain its cutting performance for longer. One advantage of top hammer bits is their versatility, as they can be used for a wide range of drilling applications and are suitable for both surface and underground drilling. They also offer high drilling speed and efficiency, allowing operators to complete drilling projects more quickly.

Jaw Pads

Jaw pads are designed to improve the grip of drilling tools, providing a more secure and comfortable hold. They help prevent slippage or loss of control, allowing operators to exert greater force and accuracy during drilling operations. The use of jaw pads can help reduce the transfer of vibrations from the drill to the operator's hand, minimizing discomfort and fatigue during extended drilling sessions. This is especially beneficial in high-impact drilling applications that generate significant vibrations. Jaw pads provide an added layer of protection for the operator's hand by reducing the risk of injuries caused by repetitive drilling motions or excessive tool vibrations.

Lifting Swivels

In the drilling industry, a lifting swivel is an essential component used in the handling and operation of drilling equipment. It is designed to provide a rotational connection between the drilling rig and the drill string, allowing for the efficient lifting and rotation of various components during drilling operations. A lifting swivel enables the transfer of torque and axial load while allowing rotational movement between the drilling rig and the drill string. It helps prevent the formation of torque-induced stresses in the lifting cables or hoisting system. Our lifting swivels are robust and heavy-duty devices due to the demanding conditions encountered in drilling operations. They are engineered to withstand high loads, resist corrosion, and function reliably in harsh environments

Adapters

Adapters for rock drilling are an essential component of drilling systems used in mining, quarrying, construction, and geotechnical applications. These adapters are used to connect the drill bit to the drill string, allowing for the transfer of rotational force and torque from the drill rig to the bit. Adapters for rock drilling are critical components of the drilling system and play a significant role in the overall drilling performance. The quality and compatibility of the adapter with the drilling rig and bit can have a significant impact on the drilling efficiency and accuracy.